1.Machine model: A-8504

2.Ensure machine can working stable,machine case use the steel material

3.PLC mirco-computer controls the machine,Digital parameter setting,automatic output.

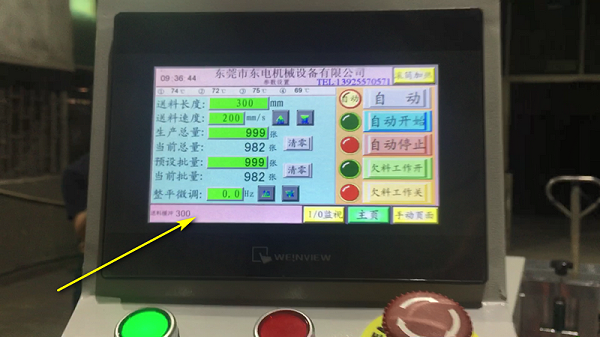

4.Easy operate with high efficiency by import servo system and magnetic braking system.

5.Function: Putting PE protection film ,cutting into 2-3 pieces ,static dealing,corona treatment, flatten ,cutting in to sheet.

Machine Picture view:

Machine working vedio:

1. Machine suitable for PVC PET ,APET ,PETG rigid film.

2. Machine has flatten and cutting function.

3. Max width :800 mm. 4 oil cylinder heating for flatten

4. mainly customer is the material supplier.

| Machine Model | A-8504 |

| Voltage | 380V .3 Phases 5 line ,60HZ |

| Output Power | 8KW |

| Max raw roll material diameter | 500 mm |

| Max width of roll material | less than 800 mm |

| Material thickness | 0.18-0.8 mm |

| Precision | ≤ ±0.25 mm |

| Heating Cylinder | 4 cylinders |

| Air compressor needed | 0.6 MPA, 350l/mi |

| Machine speed | 30 m/minute |

| Machine size | 4700*1540*1300 mm(L*W*H) |

Machine working vedio:

machine details view:

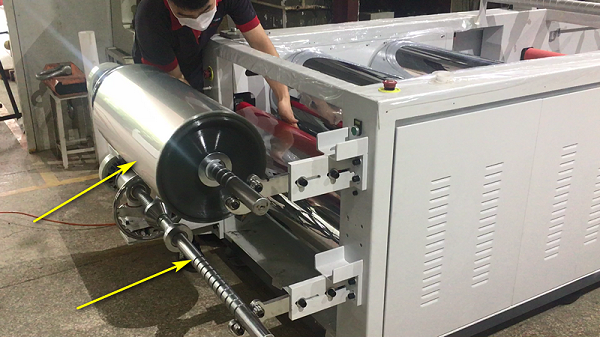

1.machine loading by roll material ,like PVC PET transparent roll.the mainly funciton is Plastic film Roll to sheet cutting. you can choose:250MM diameter*2 roll ,or one 500mm diameter*1 roll.please see the pictures.

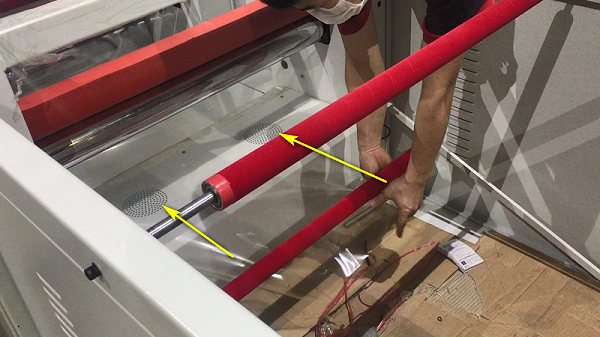

2.Plastic film flatten working by cylinder tube heating ,electric heating tube and oil inside ,oil function is keep the temperature.4 cylinders ,the temperature setting like:1-65 degree,2-70 degree,3-65 degree,4-70 degree, Plastic film Roll to sheet cutting Machine has one sensor to catch the cylinder tube working temperature.

3.Plastic film Roll to sheet cutting Machine has two cooling fan to lower the PVC PET film surface temperature.

4.static dealing ,Plastic film Roll to sheet cutting Machine to make the sheet surface static less.

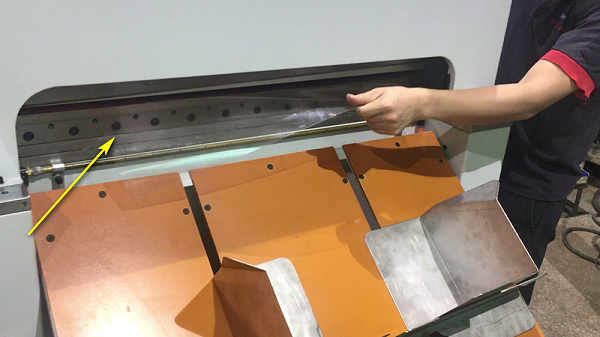

5.Vertical cutting ,Plastic film Roll to sheet cutting Machine with 2 cuters ,to get the sheet like ,600mm width with 2 cuters ,we can get 3pcs of 200 mm width sheet.

6. Cuter in the end of Plastic film Roll to sheet cutting Machine.

7.sheet holder,adjusting by sheet length and width.automatic fall down.

8.PLC+touch screen: digital display all working condition ,and production data, setting all need parameters.

9.addtional function choose by customer need:

with air shaft for heavy roll two side or one side corona treatment

with aotomatic stacker 1200 mm width sheet cutting